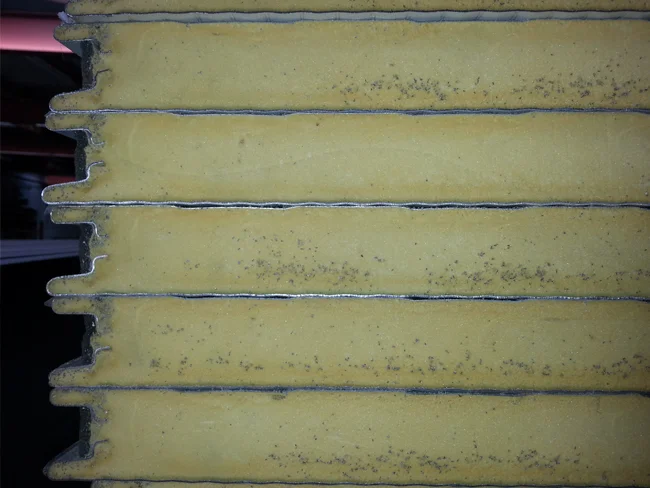

COMPOSITE FOAM PANELS

INNOVATION FOR AN EFFICIENT ARCHITECTURAL CLADDING PROCESS

Historically traditional cladding systems have required a continuous plywood substructure. For plywood to perform efficiently an air gap is required to the rear of the plywood installation. This has taken the form of top hat battens resulting in the required air gap.

This highly inefficient process implies the cost of 2 products as well as 2 tasks to install and has therefore led us to search for a product that has one labor task and uses only one product to achieve the same function as the conventional system. This product is the Composite Foam Substructure and it has been carefully selected from a wide range of choices available today.